Argo-Anleg GmbH

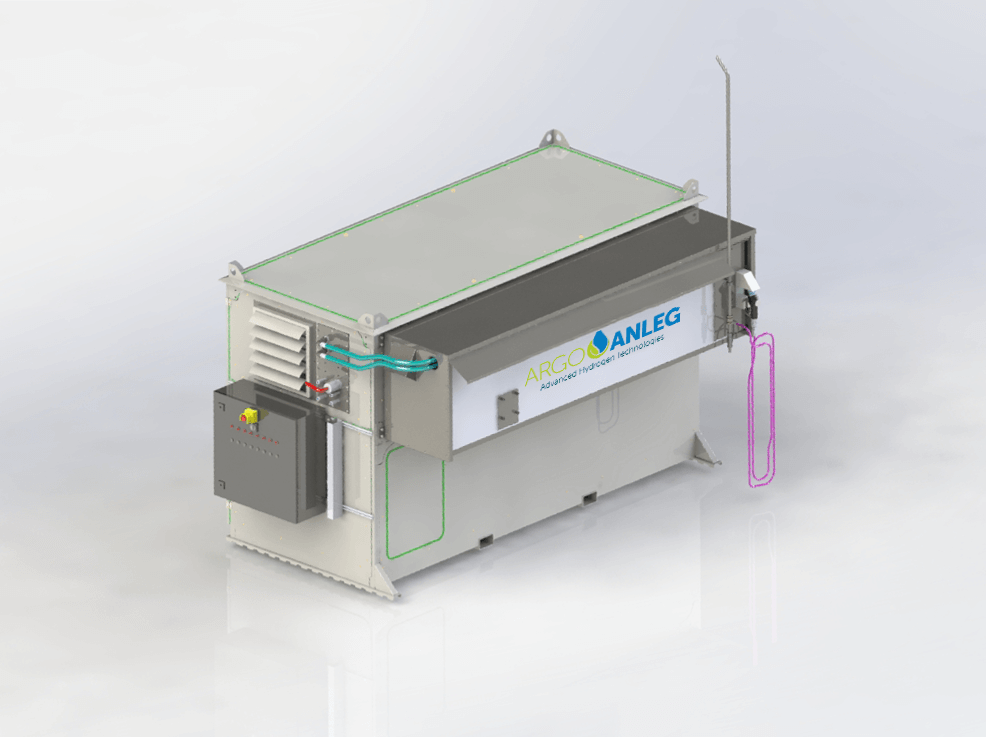

Argo-Anleg GmbH is a German company exclusively dedicated to the development and implementation of high-tech solutions in the field of hydrogen and hydrogen ecosystems. We make the energy supply and use of your company or project sustainable and fit for the future.

Activities GOcontroll is involved with:

- Deliver Moduline Controllers

- Advise in system architecture

- Wiring diagrams

- Wiring

- Software development

More information about Argo-Anleg GmbH

Paul Nutzfahrzeuge GmbH

The PH2P® Truck is a production-ready, transportable, medium-duty hydrogen fuel cell truck with a total train weight of 24 tons and a range of about 400 kilometers. The hydrogen tank system, now installed horizontally, holds 30 kilograms and the vehicle consumes about 6.5 kilograms of hydrogen per 100 kilometers. It can be fully refueled within 10 to 15 minutes. The maximum speed of the PH2P® Truck is 85 km/h, with a continuous power of 120 kilowatts and a peak power of 300 kilowatts. The continuous torque is specified at 2800 newton meters. The first 25 series production vehicles from the Paul Group will be delivered to customers by the end of 2022.

Responsibilities GOcontroll:

- Moduline IV hardware implementation

- Custom module development (IR Module)

- Development of a SAE J2799 compatible IR emitter ring for communicated refueling.

- Wiring schematics

- Software development

Note: Images belong to Paul Nutfahrzeuge GmbH

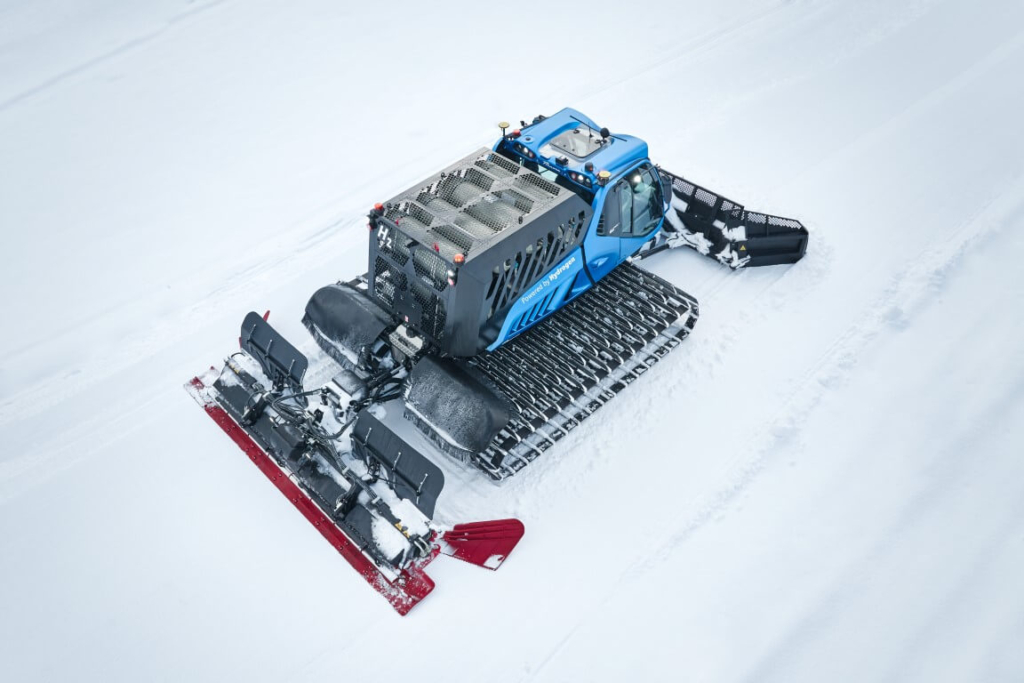

Prinoth AG

The topics of environmental protection and sustainability have gained importance in ski resorts worldwide – and not just since the last winter with little snow.

With the world’s first hydrogen-powered snow groomer, the Italian company PRINOTH, manufacturer of snow groomers, crawler carriers and vegetation management vehicles and equipment, is making an important contribution to sustainable slope preparation. The hydrogen is stored in tanks that are mounted on the back of the vehicle. The tank system (700bar) has been developed by Argo-Anleg.

In addition to the hydrogen tank system, Argo-Anleg is supporting PRINOTH in refueling the snow groomer by providing a “mobile refueling station” from Wesel, which compresses the hydrogen from a trailer to the vehicle up to 700bar.

Responsibilities GOcontroll:

- Moduline IV hardware implementation

- Wiring schematics

- Software development

Note: Images belong to Prinoth AG & Argo-Anleg

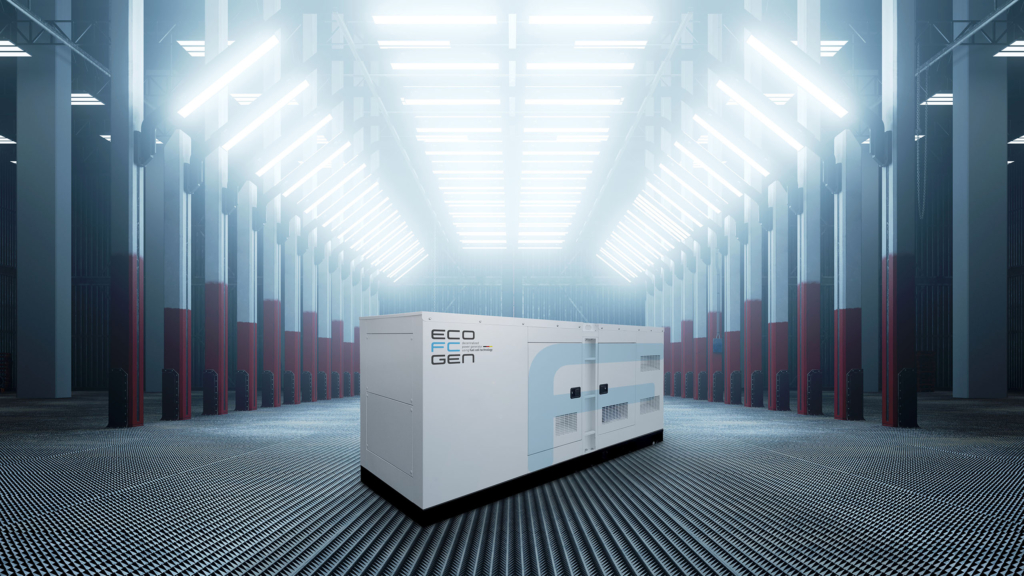

CBC GmbH & Co.KG

CBC is developping an autonomous hydrogen powered GeneratorSet based around a PEM Fuel Cell with an electric power output of 50-60kW. The first objective is to develop decentralized zero-emission power generation for remote locations in India, to supply construction sites, schools, water supply stations and farms. The final goal of this project will be a scalable fuel cell based GenSet prototype ready to serve as back up, emergency or mobile plug-in power system and therefore provide emission-free, self-sustaining electrical energy where a reliable power grid is missing.

Responsibilities GOcontroll:

- Moduline Mini I hardware implementation

- Wiring schematics

- Software development

Note: Images belong to CBC GmbH & Co.KG

Volvo Trucks

Volvo Trucks is setting up a zero-emission product portfolio, of which an important part will be hydrogen-powered fuel cell trucks. The onboard tank system, consisting of the compressed hydrogen tanks, pressure regulation and refueling interface were developped by Argo-Anleg.

Responsibilities GOcontroll:

- Moduline IV hardware implementation

- Wiring schematics

- Software development

Volvo Construction Equipment

Volvo Construction Equipment is committed to the change towards a net-zero future. Besides battery-electric solutions, where Volvo CE is already offering the largest range of commercial products, the company’s efforts also include exploring the potential of electrification trhough hydrogel fuel cell technology. Volvo CE developped the worlds first emission-free hydrogen fuel cell articulated hauler, the HX04, which was presented and demonstrated in 2022.

Volvo CE continues the development of Hydrogen fuel cell technology for construction equipment with the worlds first emission-free hydrogen fuel cell excavator. The onboard tank system, consisting of the compressed hydrogen tanks, pressure regulation and refueling interface were developped by Argo-Anleg.

Responsibilities GOcontroll:

- Moduline IV hardware implementation

- Wiring schematics

- Software development

MAN Truck & Bus SE

MAN Trucks is also setting up a zero-emission product portfolio, of which an important part will be hydrogen-powered fuel cell trucks. Before this technology can be integrated in series production vehicles, a prototype was developped. In addition to this fuel cell prototype, MAN Trucks also developped a hydrogen powered truck with an internal combustion engine.

The onboard tank system on both prototypes, consisting of the compressed hydrogen tanks, pressure regulation and refueling interface were developped by Argo-Anleg.

Responsibilities GOcontroll:

- Moduline IV hardware implementation

- Wiring schematics

- Software development

Note: Images belong to MAN Truck & Bus SE

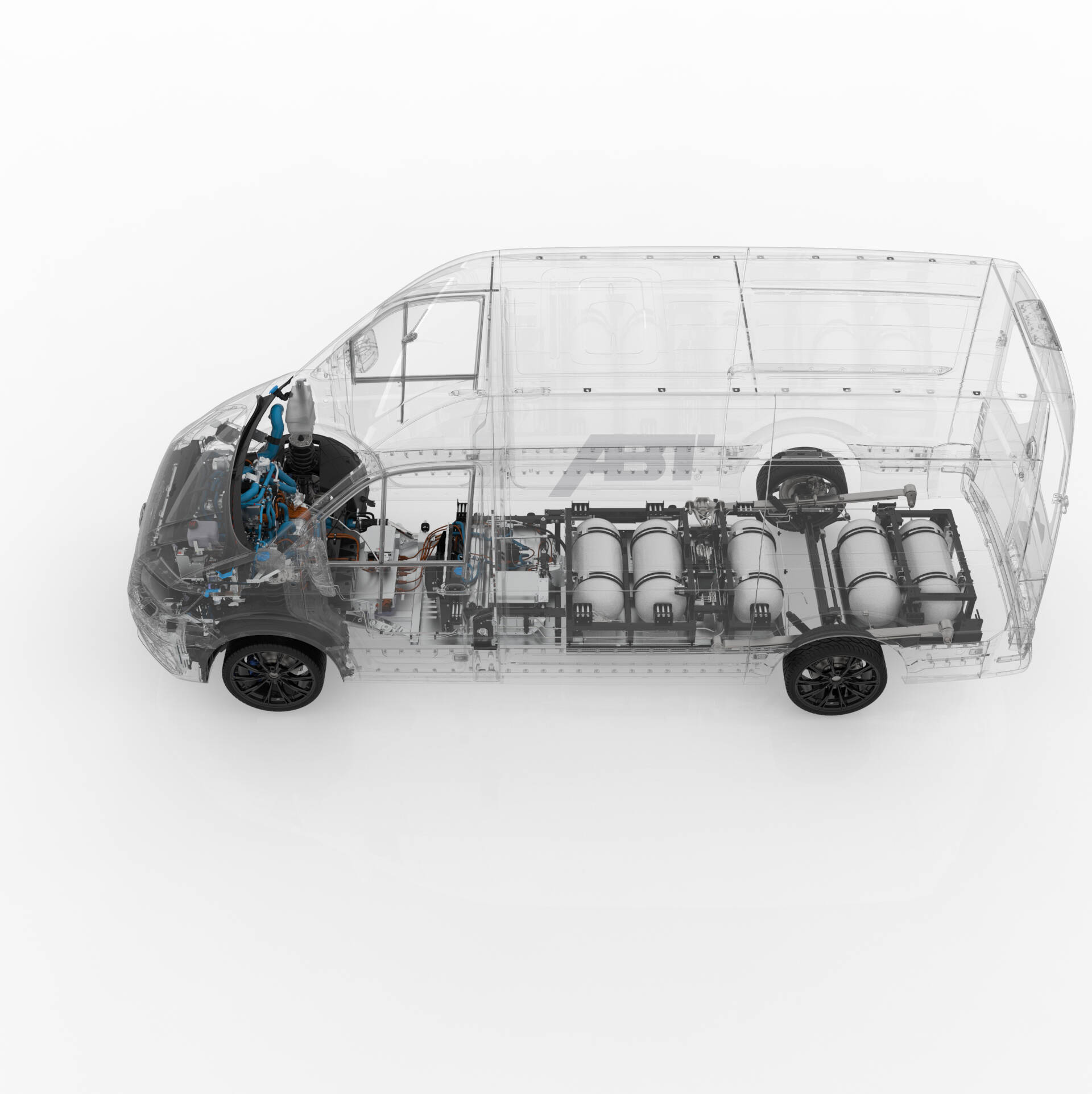

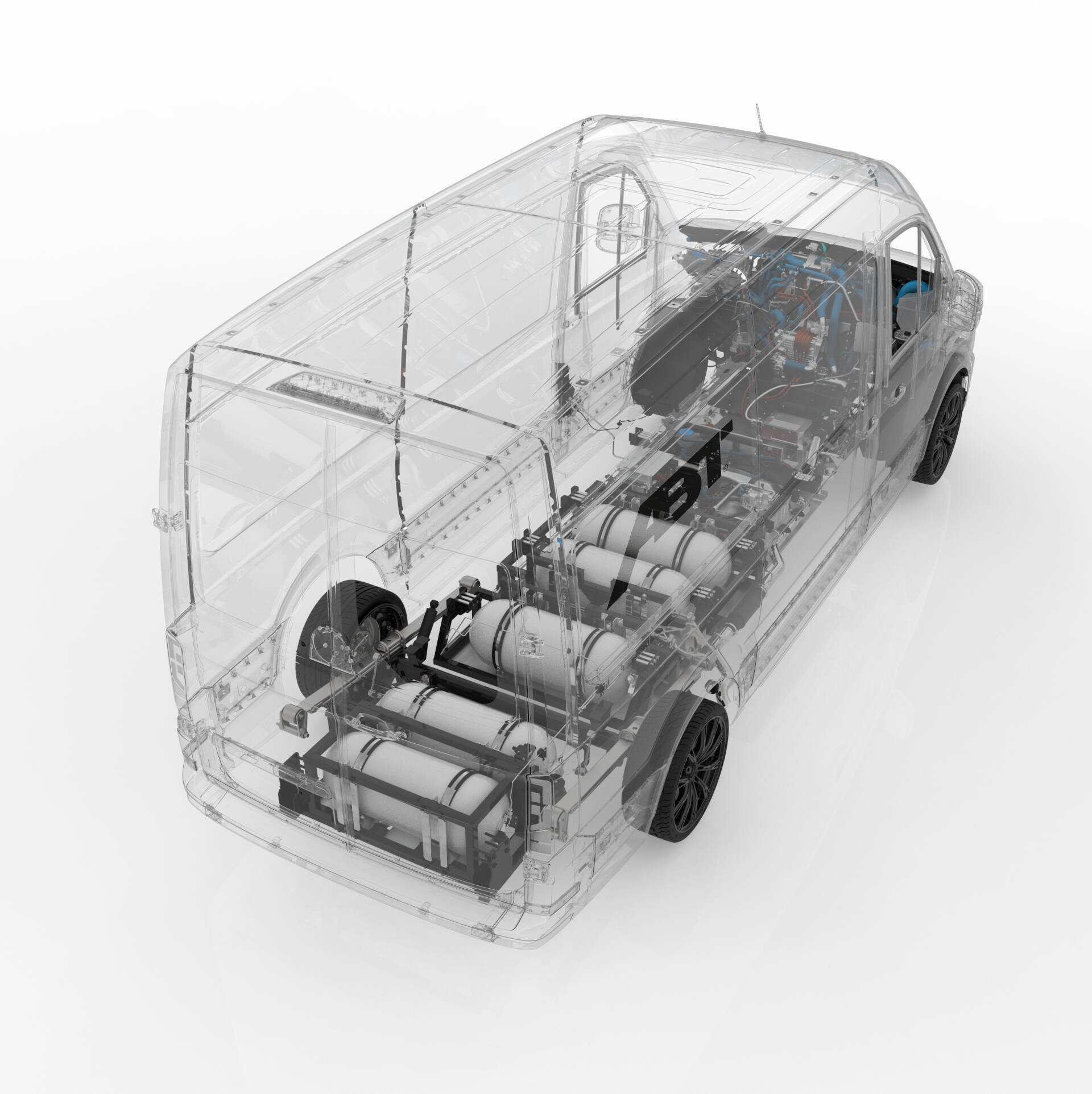

ABT e-Line GmbH

ABT e-Line focusses on the development and production of alternative powered vehicles in small and medium volumes. In coopeartion with Volkswagen Commercial Vehicles, ABT e-Line has developped and produced the electric variant of the Volkswagen Caddy and Transporter.

ABT-eLine is now focussing on hydrogen fuel cell technology and has developped two emission-free vans.

The onboard tank system on both prototypes, consisting of the compressed hydrogen tanks, pressure regulation and refueling interface were developped by Argo-Anleg.

Responsibilities GOcontroll:

- Moduline Mini I hardware implementation

- Wiring schematics

- Software development

Note: Images belong to ABT e-Line GmbH

Liebherr

Liebherr is a German-Swiss multinational heavy equipment manufacturer based in Bulle, Switzerland, with its main facilities and origins in Germany. The company consists of over 130 companies organized into 11 devision; earthmoving, mining, mobile cranes, concrete technology, maritime cranes, aerospace and transportation systems, machine tools and automation systems, domestic appliances and components.

Liebherr is pushing forward to a sustainable future; phasing out fossil fuels and preparing solutions to decarbonize construction sites, gravel plants, etc. The Liebherr plant in Bischofshofen celebrated two groundbreaking events; the presentation of the first large wheel loader with a hydrogen engine and the opening of the first hydrogen filling station in the state of Salzburg.

The L 556 H is the world’s first wheel loader with a hydrogen engine.

For more information about the L 556 H, please visit the Liebherr article: please click this link

The onboard tank system on both prototypes, consisting of the compressed hydrogen tanks, pressure regulation and refueling interface were developped by Argo-Anleg.

Responsibilities GOcontroll:

- Moduline Mini I hardware implementation

- Wiring schematics

- Software development

Note: Images belong to Liebherr