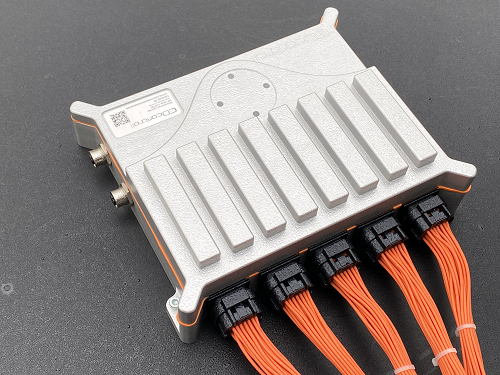

A robust controller for direct use in the field.

One of the core requirements of the GOcontroll Moduline is the electrical and mechanical robustness. Therefore the controller is equipped with automotive connectors to ensure a stable connection between sensors – actuators – communication busses etc. and the controller. The complete enclosure exists of two aluminium CNC milled parts.

The Moduline II, III and IV share the same enclosure and are pin compatible. This enables the user to upgrade their controller platform without the need of re-routing cables or changing mounting plates.

Anodized aluminium enclosure.

The enclosure provides four fundamental functions.

The modules inside the controller are plugged in depending on the application. These modules need to be mechanically supported to ensure a reliable mount during vibrating events.

For modules controlling heavy electrical loads, heat dissipation is a point of attention. The design of the enclosure in combination with the architecture of the modules provide the possibility to transport heat from the module into the enclosure.

The enclosure function as the Faraday cage principle. The electronics inside are shielded against electrical emissions from the environment which will increase the stability from the control system.

Finally the enclosure protects the electronics against mechanical impacts. During field testing and prototype build, some dropped tools or lost steel chips are imaginable. No problem for the Moduline.

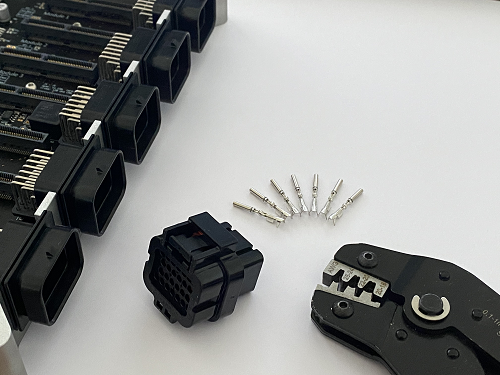

Robust connections.

To create reliable connections, GOcontroll has implemented automotive connectors into the Moduline design for interfacing the modules. For the communication over Ethernet and/or USB two M12 connectors are available. GSM, WLAN and GPS antenna’s are connected using SMA connections.

The connectors to interface the controller are able to use for sensor signals and power control. It doesn’t matter where the modules are placed, each pin is able to drive loads up to the maximum ratings provides in the modules data sheet.

Information and controller status.

During development, status information en tractability is important. When working in the field and a remote connection needs to be made, controller specific information needs to be available instant.

The enclosure is equipped with 4 RGB status LED’s which can be programmed in the Matlab – Simulink and/or Node-RED environment. This provides the possibility to see the status from the controller in one view.