Introduction

A modular controller helps create stable cheese-aging conditions with clear insight and easy automation.

Introduction

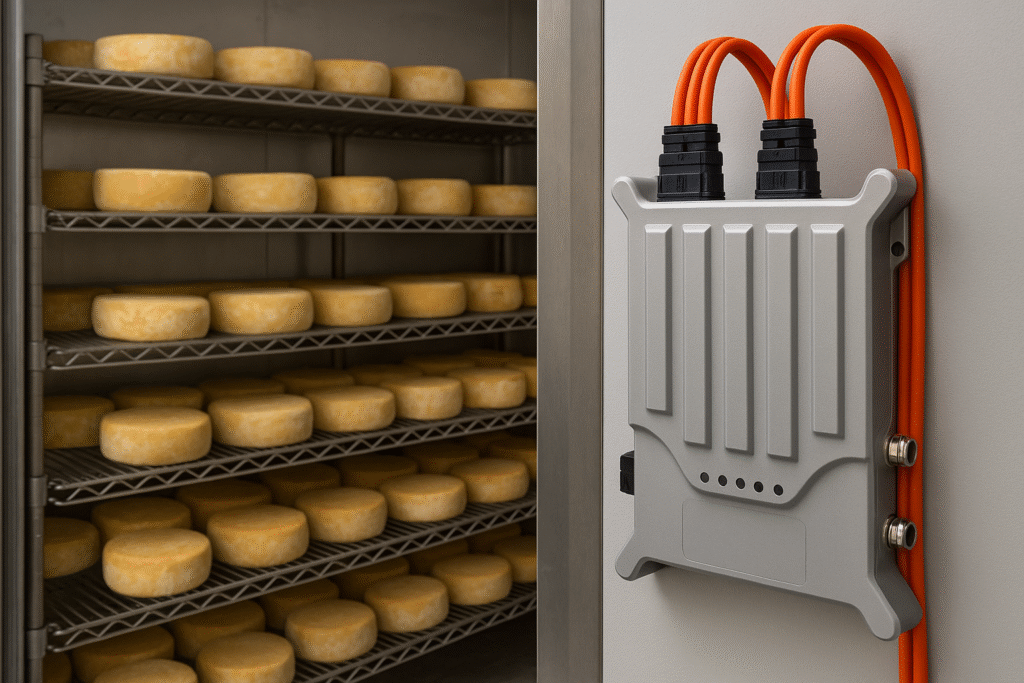

Cheese aging needs steady conditions to reach the right flavor, aroma, and texture. Even small shifts in humidity, temperature, or airflow can change the final product. With the GOcontroll Moduline Mini I, producers can build a compact and reliable chamber that stays stable throughout the entire aging process. The controller reads sensors, drives actuators, and uses clear logic to keep the climate inside the chamber consistent. As a result, researchers and artisan makers gain predictable and repeatable outcomes across many cheese types.

A Compact Platform for Controlled Aging

The Moduline Mini I offers four module slots, so users can combine input and output modules to match the chamber design. Its CNC-milled aluminium housing protects the hardware in humid or cold environments. Because the controller supports several communication options, including CAN and optional wireless interfaces, it fits both research labs and small production rooms.

Users can install temperature probes, humidity sensors, and airflow sensors on input modules. Output modules can drive fans, heaters, humidifiers, dehumidifiers, or dampers. Therefore, the chamber reacts quickly to changes and stays within a narrow climate range.

Stable Temperature, Humidity, and Airflow

Cheese aging depends on steady climate control. Because of this, the Moduline Mini I reads temperature, humidity, and airflow values many times per second. It then adjusts fans, heaters, or humidifiers right away. This quick reaction keeps the chamber stable, even when outside conditions shift.

In addition, the controller smooths out rapid changes, so cheese ages at a constant pace. Airflow also plays a key role. It affects moisture loss and the way the rind forms. Therefore, users can tune fan speed or damper position to match each stage of the aging process. As a result, they get a chamber that behaves the same way every day.

Automating Cheese Handling

Many cheeses need flipping to age evenly. However, manual flipping takes time and often leads to differences from batch to batch. With the Moduline Mini I, users can add small motors or servo arms that turn cheese wheels on a set schedule. This movement spreads moisture and heat more evenly across the cheese.

Furthermore, the controller records each flip. Because of this, producers can compare flipping patterns with temperature or humidity trends. This simple link gives them new insight into how handling affects flavor, texture, and quality. It also reduces daily labor, which helps both research teams and artisan makers.

Easy Monitoring Through Node-RED

Node-RED comes preinstalled on the controller. It gives users a simple visual tool to monitor chamber values and create custom workflows. Because Node-RED supports many dashboard elements, producers can track:

-

Real-time temperature

-

Humidity levels

-

Airflow rate

-

Actuator states

-

Flipping cycles

-

Profiles for specific cheese types

They can also record long-term data to compare batches later. This helps both artisan producers and researchers improve consistency.

Recipe-Based Profiles for Repeatable Results

Many cheeses follow clear ripening stages. With the Moduline Mini I, users can create recipe profiles that adjust conditions based on time. For example, the first week may need high humidity, while later stages may require more airflow. The controller changes settings automatically as each stage begins.

Because the logic runs locally, response times stay short and the chamber stays stable even when network connections drop. This supports quality control and simplifies training for new staff.

A Scalable Tool for Experimentation and Production

The modular design of the Moduline Mini I allows systems to grow over time. Users can start with a small test chamber and later expand with more sensors or actuators. Its robust housing and flexible software stack support long-term use in both research and artisanal environments.

Therefore, the controller works well for experimental development, tasting studies, and full artisan production. With stable control, clear dashboards, and recipe automation, it helps producers reach better and more repeatable results.

Moduline IV linear actuator control delivers precise motion using half-bridge outputs, feedback inputs, and Simulink-based control loops.

Moduline IV enables precise, programmable scent delivery for 5D-Cinema shows, creating reliable and immersive aroma effects.

Moduline Mini I mushroom environment controller enables stable humidity, CO₂, airflow, temperature, and lighting control with Simulink and Node-RED dashboards.