Introduction

A flexible controller helps small manufacturers unify and automate mixed packaging equipment with clear insight and stable performance.

Introduction

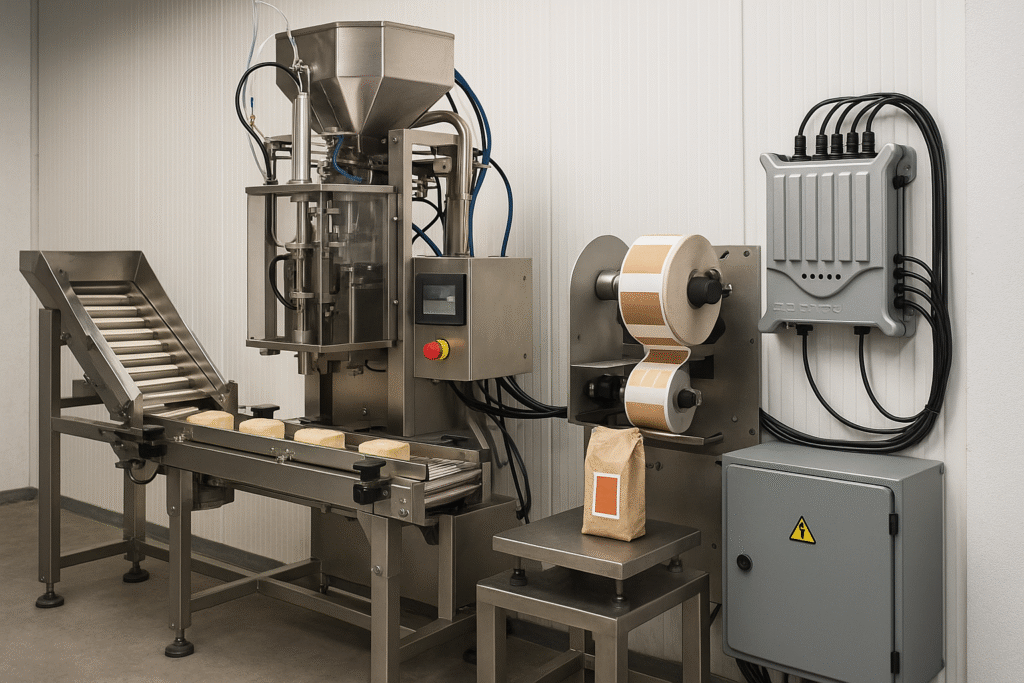

Packaging lines often grow from a mix of machines. Many small manufacturers use feeders, conveyors, sealers, labelers, printers, and weighers from different suppliers. Because these devices do not share a common controller, the line can feel fragmented and hard to manage. The GOcontroll Moduline IV solves this problem. It provides a strong, modular control platform that coordinates every step of the process. With digital I/O, analog inputs, CAN interfaces, and expansion modules, the controller keeps the entire line in sync. As a result, teams improve speed, quality, and daily workflow.

A Versatile Base for Any Packaging Setup

The Moduline IV uses an NXP i.MX 8M Mini processor and supports eight module slots. It also includes four CAN 2.0B interfaces, a LIN interface, and Ethernet. Its CNC-milled EN-AW5083 aluminium housing offers durability in busy production areas.

Users select modules that match the needs of their line. Output modules can switch motors, pneumatic valves, or printers. Input modules read sensors for speed, fill levels, weight, and product detection. Because of this modular approach, the controller adapts easily when the line grows or changes.

Smooth Conveyor Flow and Fast Machine Timing

Steady conveyor movement is vital for most packaging work. The Moduline IV reads sensor data rapidly and adjusts speeds right away. Therefore, products stay spaced correctly as they move through the line.

Furthermore, the controller triggers labelers, printers, and sealing steps at the right moment. Since the logic runs directly on the device, the response stays fast and predictable. This keeps the entire process smooth, even when the line speeds up.

Reliable Detection and Quality Monitoring

Good product flow depends on smart sensing. The Moduline IV reads position sensors, light gates, fill sensors, and weight signals many times per second. Because of this, the controller stops the line early when jams appear. It also flags missing items or alignment issues.

In addition, temperature or pressure sensors can support heated sealing steps or vacuum tasks. With this information, operators catch quality problems before waste builds up.

Clear IoT Dashboards Through Node-RED

Node-RED comes preinstalled on the Moduline IV. It gives users a simple way to build dashboards for live production data. They can view counts, cycle times, sensor states, and machine status from any browser.

Because Node-RED supports MQTT, HTTP, and other protocols, the line can also report data to cloud systems or local databases. Furthermore, operators can load recipes, change parameters, or start diagnostics without touching the machine.

Fast Development Through Simulink Integration

When more complex logic is needed, engineers can use MATLAB Simulink. The Moduline IV supports a dedicated GOcontroll blockset that exposes module I/O, CAN messages, and system values. After building the model, users upload it directly to the controller.

As a result, R&D teams can test motion profiles, dosing cycles, or timing strategies quickly. This approach reduces software effort and speeds up development.

Scalable Control for Evolving Packaging Lines

Small manufacturers often expand one machine at a time. Fortunately, the Moduline IV grows with them. Teams can install new modules for extra sensors, actuators, or communication links.

Its strong build and flexible software make it reliable for both compact lines and larger systems. Therefore, OEMs and R&D groups can create customizable packaging platforms with consistent control and long-term stability.

Moduline IV linear actuator control delivers precise motion using half-bridge outputs, feedback inputs, and Simulink-based control loops.

Moduline IV enables precise, programmable scent delivery for 5D-Cinema shows, creating reliable and immersive aroma effects.

Moduline Mini I mushroom environment controller enables stable humidity, CO₂, airflow, temperature, and lighting control with Simulink and Node-RED dashboards.